The 640L-II Cable Skidder delivers more horsepower and stability. Download a brochure, locate your nearest dealer and build your own.

products images and videos

The 640L-II Cable Skidder delivers more horsepower and stability. Download a brochure, locate your nearest dealer and build your own.

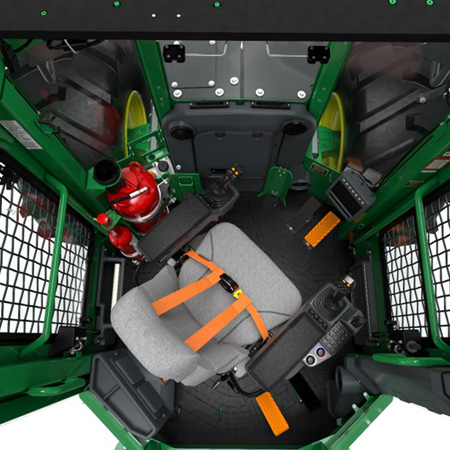

Designed by loggers for loggers, the quiet, spacious cab helps keep you more comfortable and productive – so you can boost your bottom line. The 4 m2 (43 sq ft) of window area, coupled with the 240-degree rotating seat, maximizes visibility to the task at hand while minimizing neck strain. Armrest-mounted electrohydraulic (EH) joysticks provide smooth and intuitive control of all machine functions at your fingertips. The EH joysticks also allow you to customize the button and lever layout to your preference and saves your settings when switching between operators.

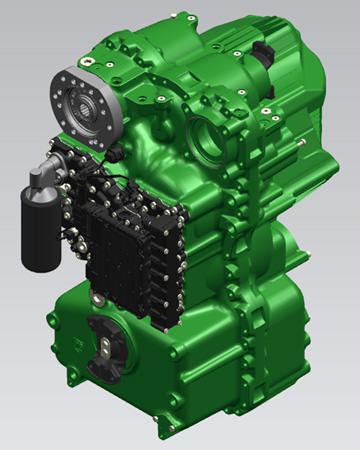

Offering loggers the best of both worlds, the Continuously Variable Transmission (CVT) combines the efficiency of the direct-drive transmission with the smoothness and ease of a hydrostatic drive. Delivering efficient power to the ground, the CVT automatically senses the load before delivering more torque to maintain the operator’s wanted speed. The CVT also eliminates the need to shift gears, which shortens the learning curve for new operators, and helps the experienced pros maximize productivity.

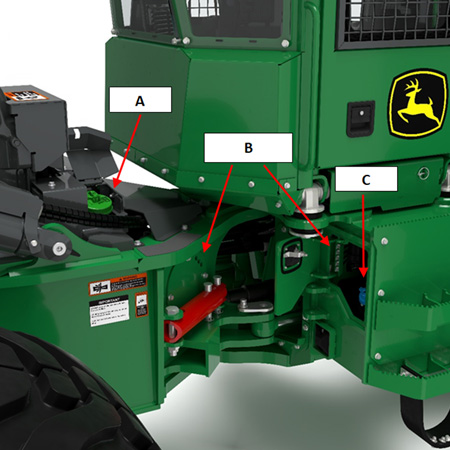

| Fill and Grease Bank Locations | |

| A | Diesel Fill |

| B | Grease Banks |

| C | DEF Fill |

Easy access to service components helps confirm daily checks and perform any scheduled maintenance, which ultimately minimize unexpected downtime and costly repairs down the road. The L-II lineup of skidders feature removable engine panels for wide-open access to filters and fluid level checks. Swing out cooler doors and an automatic reversing fan provide effortless cleaning of debris from the coolers. Fluid fills including fuel, DEF, and hydraulic oil can all be easily accessed from ground level, as well as daily greasing points.

Now included in base machine, the JDLink telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved production efficiency.

"*" indicates required fields

"*" indicates required fields