The 843L-II boasts significantly more horsepower for superb responsiveness. Download a brochure, view specifications and build your own.

products images and videos

The 843L-II boasts significantly more horsepower for superb responsiveness. Download a brochure, view specifications and build your own.

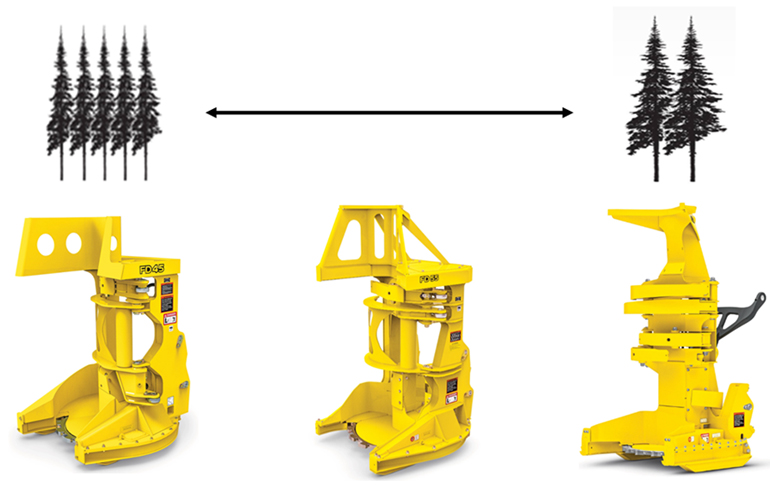

Choose from three different felling heads to match your application, tree size, and conditions, so you can maximize productivity. The twin-post FD45 and FD55 heads provide deep pockets for high-accumulation performance and are best suited for thinnings and high-production plantation harvests. The single-post FD22B head is best suited for large timber in clear-cutting applications.

|

Model |

FD45 |

FD55 |

FD22B |

|

Cut Capacity |

508 mm (20.0 in.) |

584 mm (23.0 in.) |

559 mm (22.0 in.) |

|

Accumulation Area |

0.65 m2 (7.0 sq ft) |

0.63 m2 (6.8 sq ft) |

0.48 m2 (5.2 sq ft) |

|

Ideal Timber Range |

150-350 mm (6-14 in.) |

250-460 mm (10-18 in.) |

300-500 mm (12-20 in.) |

|

Typical Application |

Plantation, thinning, and select cut |

Select cut and final felling |

Select cut and final felling |

|

Typical Operation |

High accumulation |

Mid-to-high accumulation |

Mid accumulation |

|

Weight |

2424.48 kg (5345 lb) |

2971.06 kg (6,550 lb) |

3070.85 kg (6,770 lb) |

|

Felling head specs |

|||

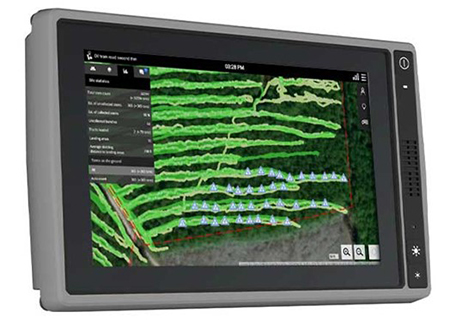

Now included in base machine, the JDLink™ telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved production efficiency.

Easy access to service components helps confirm daily checks and perform scheduled maintenance, which ultimately minimizes unexpected downtime and costly repairs. The L-II lineup of Wheeled Feller Bunchers feature removable engine panels for wide-open access to filters and fluid level checks. Swing out cooler doors and an automatic reversing fan provide effortless cleaning of debris from the coolers. Fluid fills including fuel, diesel exhaust fluid (DEF), and hydraulic oil can all be easily accessed from ground level, as well as daily greasing points.

Less fatigue means more output. Your operators will have what they need to be comfortable and productive in the cab of an L-II series wheeled feller buncher.

"*" indicates required fields

"*" indicates required fields