Owners, operators, and maintenance personnel will benefit from the big improvements found in the 744 P-Tier loaders. View all features, specs and download a 744 P-Tier brochure.

products images and videos

Owners, operators, and maintenance personnel will benefit from the big improvements found in the 744 P-Tier loaders. View all features, specs and download a 744 P-Tier brochure.

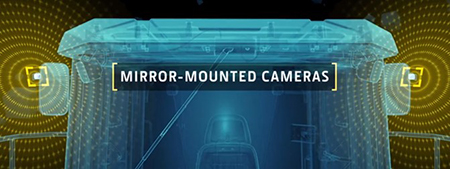

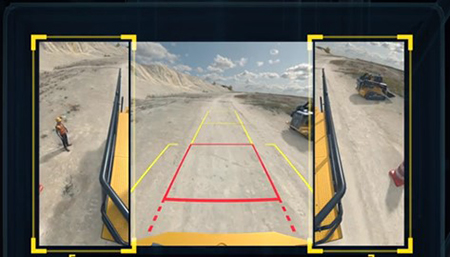

The addition of enhanced visibility and radar object detection systems improves situation awareness and can help prevent costly damage to machines and equipment. The addition of the advanced vision system and obstacle intelligence can help lower total cost of ownership and machine downtime.

Production class P-tier loaders will continue to utilize the durable axles implemented with the K-II series machines. The 744 and 824 will continue to use the TMV axles while the 844 continues to use the ZF MTL axles.

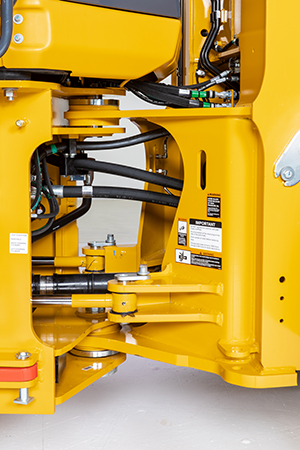

Electrohydraulic (EH) controls allow for increased functionality to customize machine operations. Operators can adjust settings based on preference to increase productivity across a range of jobsite applications.

| Quick Shift | EH Precision Mode |

| Diff Lock | Increment Counter |

| Soft Stop Disable | Add Truck |

| Add Bucket (if equipped) | Horn |

| Aux Electrical Output (if equipped) | |

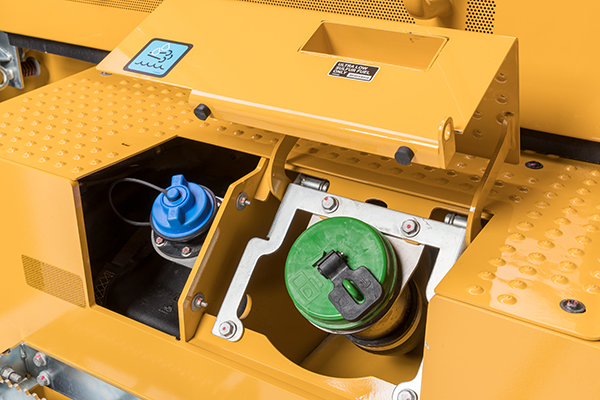

With improvements to the electrical and hydraulic routing and features such as ground level servicing and Quad Cool, customers get an upgraded serviceability experience.

P-tier production class loaders pack more power and burn less fuel than previous series machines helping increase productivity to keep up with all the demands of the sites they work on.

| Net Horsepower | |||

| K-series | P-tier | Percentage Increase | |

| 744 | 304 | 315 | 3 percent |

| 824 | 333 | 343 | 3 percent |

| 844 | 380 | 417 | 9 percent |

| 844 AH/904 | 401 | 429 | 7 percent |

The redesigned cab in the P-tier John Deere Production Class loader lineup features improvements that provide operators with a first-class work environment. The range of creature comfort options are intended to keep operators comfortable and productive no matter what task at hand.

Selecting the About button on the main menu of the monitor, then going down to SSM feature button the next screen takes you to a menu where you can view each button on the SSM and learn more about each feature.

Loaders in this size class are expected to last multiple lives and total cost of ownership is a key factor in upfront purchasing decisions. Extend the life of your machine with Powertrain Re-Life Plus Program that provides you with one more option to extend the life of your equipment without compromising the performance and reliability you have come to expect from it.

SmartWeigh™ is a John Deere designed and supported payload weighing solution that delivers accurate measurements, dynamic weighing capabilities, and is easy to calibrate. For those not sold on whether or not a payload weighing solutions is a fit for your application, John Deere offers a low cost 250-hour trial period that provides you full SmartWeigh™ capabilities to help enable you to make the decision.

"*" indicates required fields

"*" indicates required fields