The 755K Crawler Loader features a smooth hydrostatic drivetrain, spacious and quiet cab, an innovative on-demand cooling system, and EPA FT4/EU Stage IV-compliant engine.

products images and videos

The 755K Crawler Loader features a smooth hydrostatic drivetrain, spacious and quiet cab, an innovative on-demand cooling system, and EPA FT4/EU Stage IV-compliant engine.

Looking for a way to increase productivity by keeping operators comfortable? All K-Series cabs are comfortable, quiet, and more spacious than previous models. Operators will appreciate fatigue-beating ergonomics that include extensive leg room, wide doorways, and user-friendly pull-type latches to ease entry and exit from both sides of the machine.

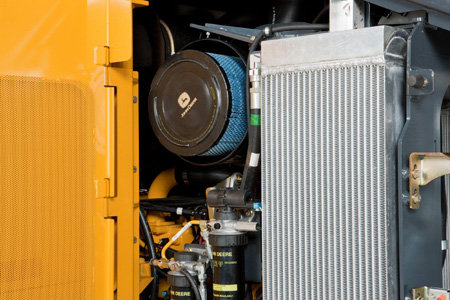

Uptime on a jobsite isn’t demanded, it’s expected. Ensuring you have reliable equipment, and the ability to conveniently perform daily service checks and maintenance is key. Easy to access service doors, onboard diagnostics, automatic filter cleaning, and an innovative cooling system set John Deere crawler loaders apart from the competition.

State-of-the-art controls put a crawler loader operator in complete command of a whole arsenal of highly productive hydrostatic (HST) advantages. HST steering eliminates steering clutches and brakes and enables single-lever steering, speed, direction control, and counterrotation. With different options to choose from for both hydraulic and transmission controls, operators can select the layout that will best fit their style.

Proven technology and a building block approach based on a solid foundation of reliable John Deere engines has led to the integration of Final Tier 4 (FT4) engines in K-series crawler loaders. The PowerTech™ PVS 6.8L engine includes familiar components such as electronic injectors, 4-valve cylinder head, turbocharger, cooled exhaust gas recirculation (EGR), diesel oxidation catalyst (DOC), and diesel particulate filter (DPF). The engine is fully integrated into the design of crawler loaders, allowing for optimized performance and maintenance.

Crawler loaders equipped with a hydrostatic (HST) drivetrain keep operation simple and provide the confidence to conquer any task. The dual-path HST transmission delivers smooth moves, infinite speed control, and live power turns that push a full load without spilling material. For unmatched durability and maneuverability, each track is individually powered with its own pump and motor. Multiple operator preference settings are available, giving operators the flexibility to tailor machine operating characteristics.

"*" indicates required fields

"*" indicates required fields